The National Manufacturing Institute Scotland (NMIS) is a place where industry, academia and the public sector work together on ground-breaking manufacturing research to transform productivity levels, makes companies more competitive and boost the skills of our current and future workforce.

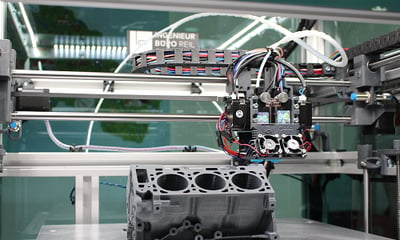

The Resource Efficient Supply Manufacturing Environment (RESuME) testbed was created to underpin NMIS Digital Factory by enabling digital connectivity and ISA-95 inspired data integration for machines and equipment. The project scope covers IIoT infrastructure for machinery & equipment located in the AFRC. There are 73 machines ranging from low tech to state-of-the-art.

To supply, install & commission IIoT sensors & gateways on all machines & equipment in the OEM & customer sandbox testbed. Data is aggregated into the XpertFactory platform via a new industrial ethernet network for further analysis & insight. The data acquired covers energy monitoring of machines, machine performance, and building monitoring, and will be accessible via local displays and remotely via the cloud.

The provision of an IIoT system that facilitates seamless, synchronised, and centralised real-time data acquisition from existing machinery & equipment enabling data processing, dashboarding, analysis, and storage. As the machines can be linked to a complete ecosystem (via local HMI’s / Dashboards / Cloud), detailed analysis of machine performance is achieved remotely providing critical insights to machine performance and machine learning opportunities.