The Advanced Manufacturing Research Centre (AMRC) is a network of world-leading research and innovation centres working with advanced manufacturing companies around the globe. The AMRC transform industrial and economic performance by making step changes in productivity, increasing competitiveness, developing new products and processes and training new talent and skills.

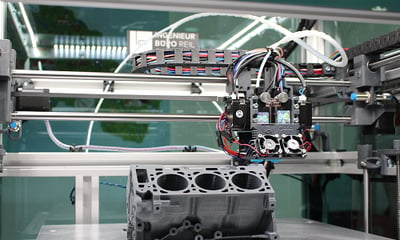

Interrupted Hybrid Manufacture (IHYM) denotes a manufacturing method which utilises metal additive technologies and CNC subtractive machining technology together on a single platform. The project scope was to advance the understanding of hybrid manufacture through investigative studies, elevating the technology readiness level and ultimately proving it a viable manufacturing method.

To connect and retrieve real-time data and aggregate the data on the XpertFactory platform to monitor and review data over time for further analysis & insight. The data acquired covered machine performance and environmental sensors. The platform was accessible via local displays and remotely via the cloud. The knowledge acquired was used to create a questionnaire to accurately estimate a parts suitability for hybrid manufacture.

Combining the data from machine and environment allowed more insight and understanding of the key control variables, which improved the quality of the component. Engineers were alerted in real-time to problems before they occurred which resulted in consistent near zero error processes.